An Unbiased View of Mhs - Material Handling Supply Inc.

Facts About Mhs - Material Handling Supply Inc. Revealed

Table of ContentsHow Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.What Does Mhs - Material Handling Supply Inc. Do?Unknown Facts About Mhs - Material Handling Supply Inc.Not known Facts About Mhs - Material Handling Supply Inc.An Unbiased View of Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. - Questions

This line is called the line of activity. forklift rental watkinsville, ga. If the bottom of this line goes beyond the stability triangle due to the fact that a tons is too hefty or expensive, or due to the fact that the forklift is not on a level surface area it will tip over. A vertical line expanding from the center of mass of the vehicle-load combination must stay inside the security triangular to avoid the forklift from tippingThis security triangular is made by connecting the 2 front wheels and the pivot factor of the rear axle. The other idea to recognize is the forklifts center of gravity. Notice that the front and back sides of the security triangle are high-lighted. When unloaded, the forklifts center of gravity is appropriate about right here.

Heavier tons change the center of gravity ahead also further. Raising the load likewise changes the center of mass forward. In order to protect against the lift from tipping, the consolidated center of gravity of the load and the lift should remain inside the security triangle (at ground level) in all times.

10 Easy Facts About Mhs - Material Handling Supply Inc. Explained

If you have a balanced load, the load is not likely to influence the side-to-side facility of gravity. https://www.tumblr.com/mhsinc30677/749115397222039552/since-1999-mhs-has-been-providing-our-customers?source=share. If you drive on a sloped surface area, your facility of gravity could pass outside of the security triangle and the lift could tip. Every forklift has an identification plate that provides vital info concerning the vehicle

To make sure that the center of mass of your forklift stays inside the stability triangular, do not attempt to raise anything larger than the identification plate allows. No matter how active you are, you have to inspect your forklift before utilizing it. If you do find something that could impact the safety and security of the lorry you need to report it right away.

Comply with the drivers handbooks supplied by the tools supplier. These guidebooks define the secure procedure and upkeep of forklifts. Bear in mind, the driver is liable for the risk-free operation of the forklift. Do a pre-operation examination prior to every change. If the forklift is utilized around the clock, check it either before each shift or after each change.

How Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.

It is finished in two components: the walk-around inspection, and, the seated examination. OSHA does not require paperwork of a day-to-day examination. It's a good concept to have a list to make sure you do not miss any kind of steps. These lists can likewise be conserved as a component of the upkeep record.

If the forklift is an exterior forklift with pneumatic tires, check the air pressure and look for too much wear on the tires. A tire with low air stress could cause the lift to tip when a load is raised.

10 Easy Facts About Mhs - Material Handling Supply Inc. Explained

Try to find splits or various other signs of wear. Inspect all fluid degrees. Inspect the engine for any type of indicators of wear, loose connections, or leaks. Wipe up any kind of excessive oil or various other combustible material. Try to find cracks or deformities in the forks, backrest, pole, and overhead guard. Check the recognition plate to ensure it is intact and understandable.

Beginning the engine. Always start the engine while seated in the operator's positionnever while standing alongside the forklift. Check all gauges and alerting lights, and the battery or gas degree. Get accustomed to the controls. Raise and reduce the forks, and turn the pole. Make certain that everything works smoothly and is clearly labeled.

Mhs - Material Handling Supply Inc. Things To Know Before You Get This

You'll need to seem the horn at intersections, and anywhere vision is blocked. Check the brakes by dispiriting the brake pedal. There must be some resistance. Establish and test the emergency brake. Check the guiding. A great deal of play or hard guiding will certainly reduce your control. Move the forklift forward a couple of feet.

Look for sparks or flames coming out of the exhaust system. If you discover anything wrong with the forklift throughout the walk-around or seated evaluation, do not operate it till it has actually been repaired.

Some Known Details About Mhs - Material Handling Supply Inc.

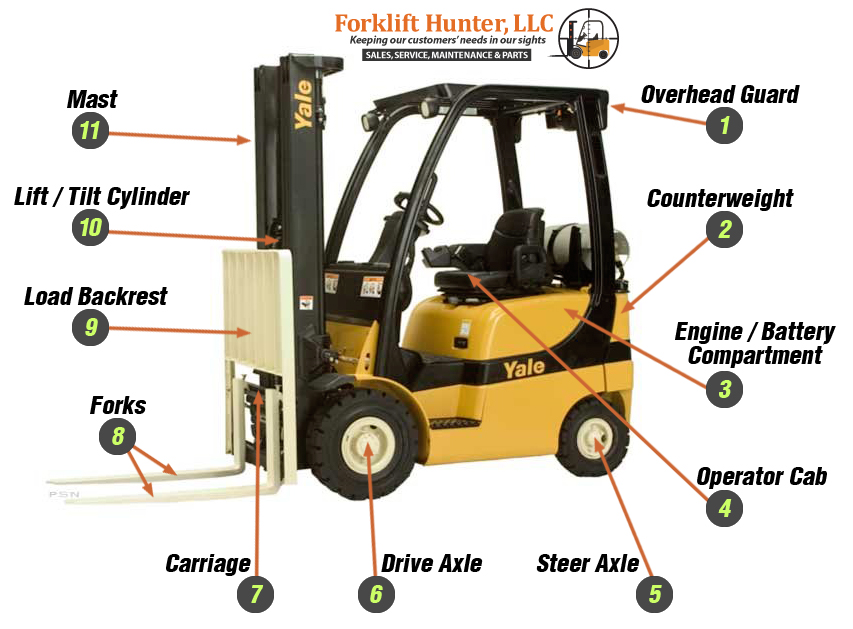

Forklifts have numerous moving parts and items that allow the forklift to operate effectively. Comprehending the terminology of the components and anatomy of a forklift is essential for effective communication with others while on the job - https://trello.com/w/mhsinc30677. Below are look at this now some of the basic attributes and components that compose the anatomy of a forklift vehicle

For the majority of forklifts, the mast is developed toward the front of a forklift and directly in the forklift driver's line of vision. Forklift masts include different areas that boost or reduced the forklift carriage in addition to the forks. These include:: Two pole stages: 3 mast phases: 4 mast sections When picking a forklift, it is crucial to familiarize yourself with the various attributes and terminology of a forklift pole: the pole's lift height, the totally free lift height and the extensive height and the lowered elevation.